Process

Hot dip galvanizing, unlike any other treatment, is the only process that achieves a convenient, economical and long-lasting effect. It is carried out by immersing the parts in a bath of molten zinc with a purity of 99.99% and which is the most recommended protection in the world to guarantee the highest resistance, in the harshest climatic conditions, to which the different types of steels are exposed.

Between the steels and the zinc an alloy is produced in the boundary layer and outwards, which is extremely beneficial against the advance of corrosion.

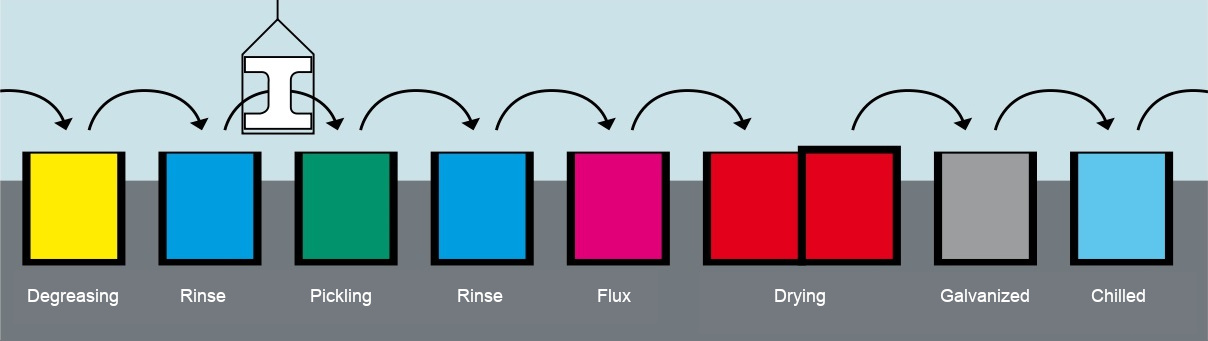

1. Degreasing. It is carried out in a hot alkaline solution, where the materials to be galvanized are immersed to remove oils and fats.

2. Rinse. It is intended for washing parts from the previous step.

3. Pickling. Immersion of materials in an acid solution (hydrochloric acid).

4. Rinse. Scavenging from acid and iron oxide salts.

5. Flux. The flux solution (ammonium and zinc chlorides) enhances the steel-zinc alloy.

6. Drying and preheating.

7. Galvanized. Immersion of the pieces in a bath of molten zinc at 450ºC to form the steel-zinc alloy.

8. Chilled. It is done in water at room temperature.

9. Termination. 100% review of the processed material.

10. Deposit. Transfer to playón for delivery or withdrawal.