Technical Notes

The quality of a coating depends on several factors: chemical preparation, raw material quality, surface roughness, zinc temperature, immersion time, extraction and cooling rate, and steel composition.

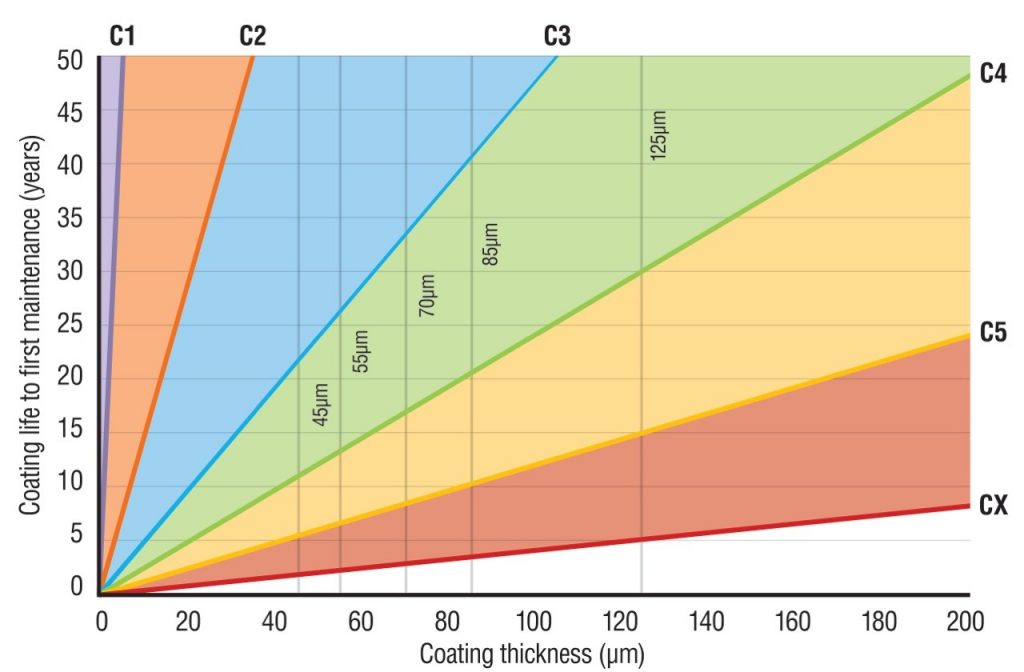

The duration of a galvanized coating is directly proportional to its thickness. For example, for thicknesses between 70 and 100 microns, obtained in hot dip galvanization, the estimated duration is:

- In rural environments: over 30 years

- In urban environments: more than 20 years

- In marine environments: over 15 years

- In industrial environments: 12 to 15 years

Average value in the set of pieces that constitute the test sample

Material

Thickness micrometers (um)

Mass g/m2

Allowable deviation in the individual pieces that constitute the test sample

Steel thickness: <1mm

50

360

-15%

Steel thickness: >=1mm hasta <3mm

50

400

-15%

Steel thickness: >=3mm hasta <6mm

50

500

-15%

Steel thickness: >=6mm

50

610

-10%

Casting parts

50

500

-10%